Luxury Tailoring Production

Artisanal quality and an efficient production process

Luxury Tailoring Production

For over sixty years, Confezioni Gallia has been a trusted name in Italian tailoring production for luxury brands, international fashion houses, and independent designers. Our approach combines artisanal mastery with a structured industrial organization, creating a unique balance that has been perfected over time and continues to evolve.

We merge the intelligence of skilled hands with the precision of industry. This is our vision of tailoring production: authentic, fully traceable, and ready to meet the most complex demands of the contemporary market.

Production efficiency: where tailoring meets industry

Being artisans is not enough when working with an international brand. Precision in timing, controlled costs, and reliable operations are essential. That is why we have learned to balance sartorial flexibility with rigorous organization.

For us, production efficiency means designing every stage of the process with clarity and responsibility. The essence of craftsmanship remains at the core but is made repeatable and scalable through a solid and structured method.

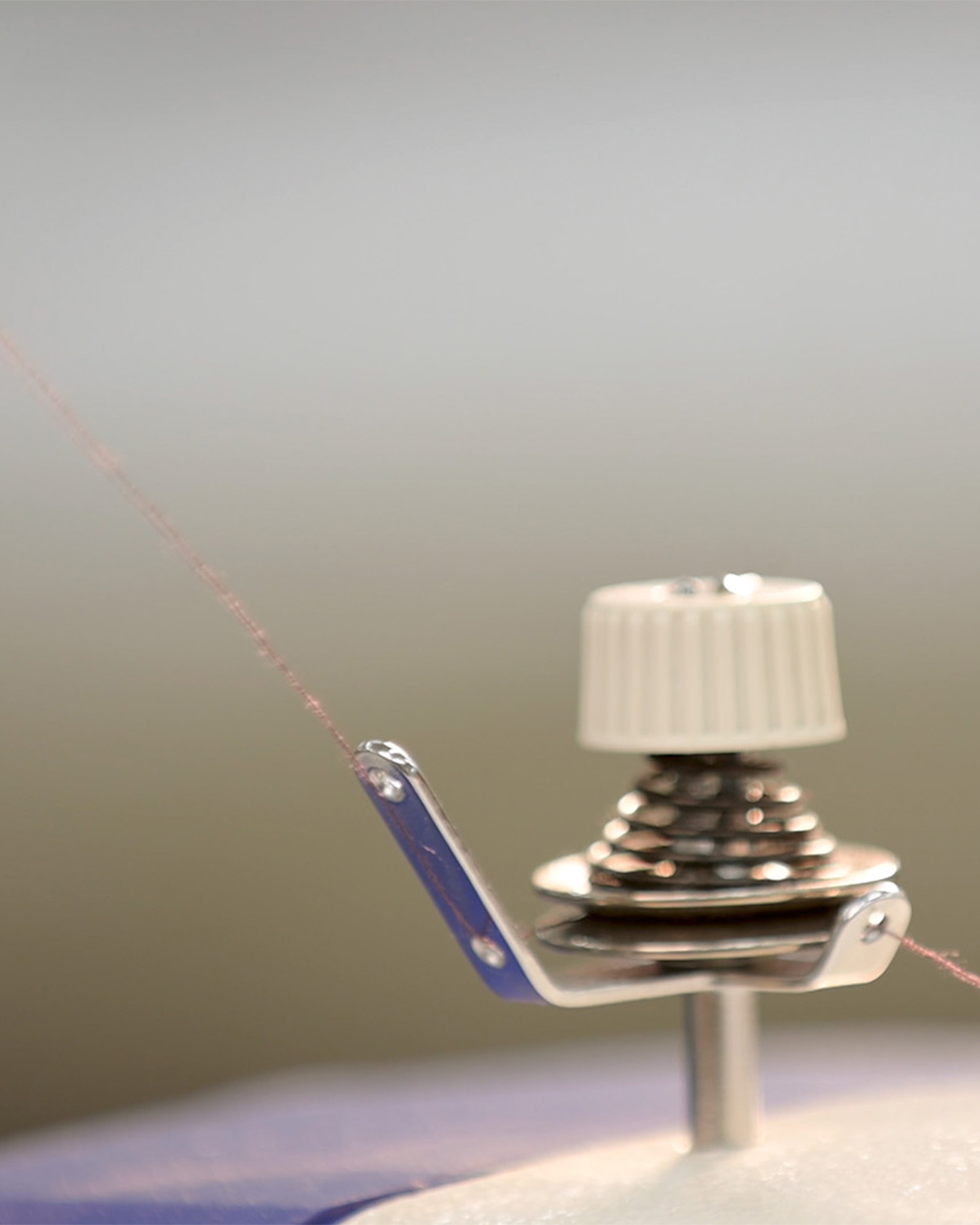

Our design process is fully digital, and fabric cutting is managed with CAD software. We monitor the entire production cycle and continuously invest in the training and growth of our team, both technically and personally. This allows us to maintain high and consistent standards, even for large-scale orders.

It is not about sacrificing artisanal care, but rather supporting it with a system that works. This way, our clients experience the attention of a tailor’s workshop while benefiting from the reliability of an organized and efficient production process.

Our base is in Veneto, where we coordinate an integrated tailoring supply chain involving carefully selected partners and highly skilled personnel. Every step is transparent and fully traceable, right up to the finished garment.

This is what we mean by sartorial efficiency:

- A method designed to minimize errors and eliminate wasted time

- A streamlined workflow that never compromises attention to detail

- Constant alignment between pattern-making, cutting, and sewing

- A stable, motivated, and well-trained team

- Consistent production, always guaranteed

In the end, this blend of craftsmanship and structure is our answer to those who seek genuine, professional quality.

If you want to see how we optimize every stage of our process, visit our dedicated manufacturing process page.

Artisanal shirtmaking: the invisible value

Behind a well-crafted shirt, there is not only the skill of the hands but also a precise method designed to ensure product quality.

This quality also stems from efficiency—an organization that allows us to work with focus and care, without rushing, while optimizing every step of the process.

At Confezioni Gallia, every stage of production is designed to honor the time and expertise of our people. This means minimizing waste, streamlining operations, and maintaining a smooth, continuous workflow.

The result is not just a beautiful garment, but a product born from intelligence, sustainability, and measurable quality.

Every detail is traced and carefully considered to ensure a shirt that meets the highest luxury standards—from fabric selection to cutting, sewing, and quality control.

Our production model combines sartorial craftsmanship with an organizational culture. This balance makes the difference, especially for brands seeking a reliable partner capable of delivering not just high-quality garments, but a quality that is consistently repeatable, season after season.

The artisanal gesture remains at the core. But it is the method that makes it sustainable today.

Why it works

-

Optimized processes to minimize errors and inefficiencies

-

Respect for each department’s time, without ever compromising attention to detail

-

Seamless communication between pattern-making, cutting, and assembly

-

A trained, stable, and results-driven team

-

Quality control standards fully integrated into the production flow

A tailoring supply chain looking to the future

We believe the future of Italian tailoring lies in the union of artisanal expertise and technological innovation, not as a compromise but as the ideal synthesis. In an era where digital technologies are redefining production, we work to integrate the soul of the atelier with the precision and efficiency of Industry 5.0.

Every day, we support brands that build luxury on authentic values. We assist them discreetly, offering a full tailoring service that is operational, traceable and consistent, without ever compromising on attention to detail.

The beating heart of Confezioni Gallia, in Veneto, is where intelligent machines and skilled hands work together. We leverage IoT-connected machinery, smart cloud systems and near real-time data to monitor and optimize every stage. This allows us to uphold the highest quality standards, even on complex productions.

In this way, we ensure

- Replicable and consistent processes, even at scale

- Adaptability to change without losing authenticity

- Constant quality thanks to integrated, data-driven controls

- Transparency at every step, from design to the finished garment

This is Industry 5.0 tailoring, where technology does not replace the artisan’s gesture but enhances it. Here, the method becomes part of the mission, not a limitation.

Our vision goes beyond the product. We want to be recognized for our ethical commitment and the human value we bring to every collaboration.

We believe in a fashion built to last, shaped by conscious choices, exceptional materials and skilled hands.

Because true beauty is not measured only by the eye, it is felt in the care, revealed in the details and passed on through time.

Blog

Stories, values, and materials that make Made in Italy a worldwide recognized excellence.

Circular Fashion: How to Redesign Fashion Manufacturing

What is circular fashion, and how does it apply to third-party production? Principles, models, and Confezioni Gallia’s method for sustainable fashion.

Resort or Cruise Collections 2025: Trends and Materials

Discover what resort collections are, the key trends for 2025, and how third-party manufacturing works for cruise fashion collections.

Made in Italy Fashion Production: Italian Textile Districts and Sartorial Supply Chain

Discover the heart of Made in Italy fashion production, from textile districts and luxury supply chains to craftsmanship, innovation, and sustainability.