Third-party sampling and pattern making services

Quality begins with an idea. But it is only when that idea takes shape that it truly starts to tell its story.

To create a collection that truly speaks the language of a brand, it is essential to start from solid foundations. Third-party sampling and pattern making services represent the first step in transforming a creative idea into a tangible garment — technically sound, production-ready and perfectly aligned with both aesthetic and manufacturing requirements.

At Confezioni Gallia, this means experience, precision and a tailoring-driven approach at every stage of product development.

Quality begins with an idea. But it is only when that idea takes shape that its true value emerges.

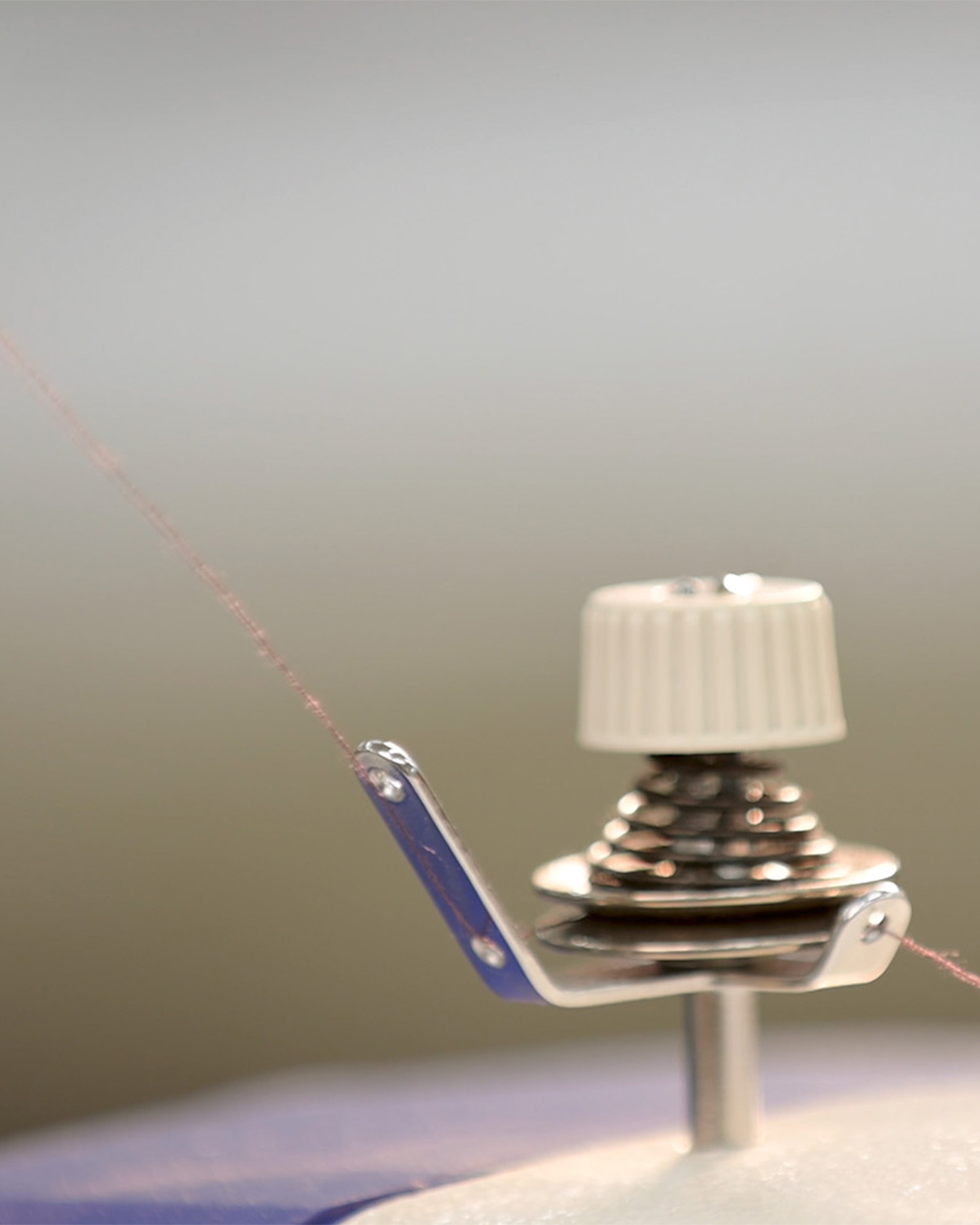

Within our tailoring workshop, specialized in third-party production for high-end brands, sampling is far more than a technical phase. It is the moment in which the DNA of a collection is defined.

Whether we are working on luxury shirts or made-to-measure garments produced in limited series, we offer an in-house industrial pattern making department capable of following every project from pattern development through to advanced prototyping. Each sample is the result of attentive listening, technical insight and deep respect for the brand’s identity.

Every day, we work to make bespoke pattern making a truly strategic service for leading international maisons.

Bespoke pattern making

An in-house, highly specialized pattern making department is one of the most valuable assets in third-party fashion production. At Confezioni Gallia, every pattern is developed through direct collaboration between the client and our technical team, composed of pattern makers with extensive experience in the luxury sector.

We work with paper patterns, CAD software and physical prototypes to define volumes, proportions and details, carefully verifying both aesthetic integrity and production feasibility at every step. This phase is crucial for anticipating potential issues, improving fit and optimizing manufacturing timelines.

Our pattern making process is never standardized. Each project is developed on a bespoke basis, according to the specific requirements of the client. Whether it involves made-to-measure shirts, structured garments or more fluid, contemporary designs, we adapt our techniques and approach with a mindset that is both sartorial and scalable.

We are also equipped to manage pattern development from scratch, as well as grading, adjustments and reworking based on client-provided patterns. This ensures maximum flexibility, precision and consistency with the brand’s expectations.

Fast sampling

Speed in sampling is a critical competitive advantage, especially for brands operating within tight fashion calendars. At Confezioni Gallia, we produce prototypes and samples within efficient timelines while maintaining high quality standards and meticulous craftsmanship.

Each sample is treated as a finished garment: finishes, details and materials fully reflect those intended for series production. This allows for a realistic evaluation of the final result, both from an aesthetic and a production perspective.

Working within a short supply chain, with selected suppliers and fully coordinated internal processes, enables us to optimize timelines and respond quickly to client requests — including capsule collections, limited editions and ready-to-deliver projects.

We are able to produce luxury shirt samples and other premium garments within compressed timeframes thanks to:

- a dedicated prototyping team;

- fully coordinated in-house departments;

- a short supply chain of reliable, certified suppliers.

From the initial sketch to the first fitting, our goal is to transform ideas into concrete, refined garments ready for production. This service is designed for both established brands and emerging designers looking to test the market with capsule collections.

For us, third-party sampling is the bridge between creativity and industrial production.

Technical consultancy and third-party design support

We have never limited ourselves to execution alone — not in over 60 years of experience.

Our objective is to actively support clients throughout every phase of product development. For this reason, we offer an integrated technical consultancy service that works alongside designers and style departments to define each garment in detail.

We analyze:

- fit and proportions;

- material selection;

- construction solutions;

- adaptability to series production.

Our expertise in industrial pattern making allows us to anticipate challenges, propose technical improvements and optimize garments for production without compromising their aesthetic identity.

Ongoing dialogue enables us to rethink designs through a more sustainable lens, reduce waste and ensure feasibility even for large-scale launches.

Scalability: from sample to production

Continuity between sampling and production is essential.

The transition from prototype to series production is one of the most complex challenges in third-party fashion manufacturing. It is not simply about replicating a garment, but about adapting its characteristics to the production chain while preserving quality, fit and aesthetic coherence.

At Confezioni Gallia, this process is managed entirely in-house and with the utmost attention. Once a sample is approved, we initiate a pre-production phase and production testing to identify optimization opportunities and define the most efficient manufacturing method.

This approach allows us to guarantee:

- maximum consistency between prototype and final product;

- optimized timelines and workflows;

- full traceability throughout the supply chain;

- constant quality control.

Our tailoring-driven approach, combined with a solid production structure, enables us to scale efficiently — from small runs to larger volumes. Each phase is monitored through a coordinated workflow: cutting, assembly, pressing and quality control.

Consistency between sample and production is what distinguishes a good supplier from a true strategic partner. It is within this balance between craftsmanship and industrial method that real production efficiency is achieved.

Choosing Confezioni Gallia as your production development partner

Collaborating with us means working alongside a tailoring ally, not just a manufacturer.

We are an Italian company with over 60 years of experience in third-party garment production, specialized in luxury shirts and made-to-measure garments.

We offer:

- advanced design and technical consultancy;

- sampling development and management;

- bespoke and industrial pattern making;

- flexible, controlled production;

- a fully Made in Italy process.

Each client is supported by a dedicated team capable of working closely with style departments, interpreting collection requirements and transforming them into impeccable finished garments.

Our mission is to translate a brand’s identity into garments that are feasible, refined, consistent and sustainable.

From the first sketch to the finished prototype, we stand by your side at every stage of development.

Would you like to create your next collection with us?

From the first sketch to the finished prototype, we support you at every stage of development.

Get in touch to discover how we can help bring your project to life.

Blog

Stories, values and materials that make Made in Italy a globally recognised excellence.

Circular Fashion: How to Redesign Fashion Manufacturing

What is circular fashion, and how does it apply to third-party production? Principles, models, and Confezioni Gallia’s method for sustainable fashion.

Resort or Cruise Collections 2025: Trends and Materials

Discover what resort collections are, the key trends for 2025, and how third-party manufacturing works for cruise fashion collections.

Made in Italy Fashion Production: Italian Textile Districts and Sartorial Supply Chain

Discover the heart of Made in Italy fashion production, from textile districts and luxury supply chains to craftsmanship, innovation, and sustainability.