3D Fashion Prototyping: What It Is and How It Works

3D fashion prototyping has become one of the most discussed topics in product development over the past few years. Often described as a technological revolution capable of replacing traditional sampling, it actually represents something more subtle and far more interesting: a new way of designing, evaluating and making decisions before a garment becomes physical.

3D sampling emerged from the need to reduce time, costs and uncertainty during the early development stages. Through dedicated software, a pattern is transformed into a three-dimensional model that simulates fit, volume and proportions on a digital avatar. At this stage, it is possible to observe how the garment “lives” on the body, identify structural issues and compare variations without immediately producing a physical prototype.

However, one key point must be clarified: 3D sampling does not eliminate tailoring, nor does it replace it. Its value becomes evident when it is integrated into a structured production process, where digital tools anticipate certain decisions while final quality remains anchored to the physical garment, real materials and sartorial control.

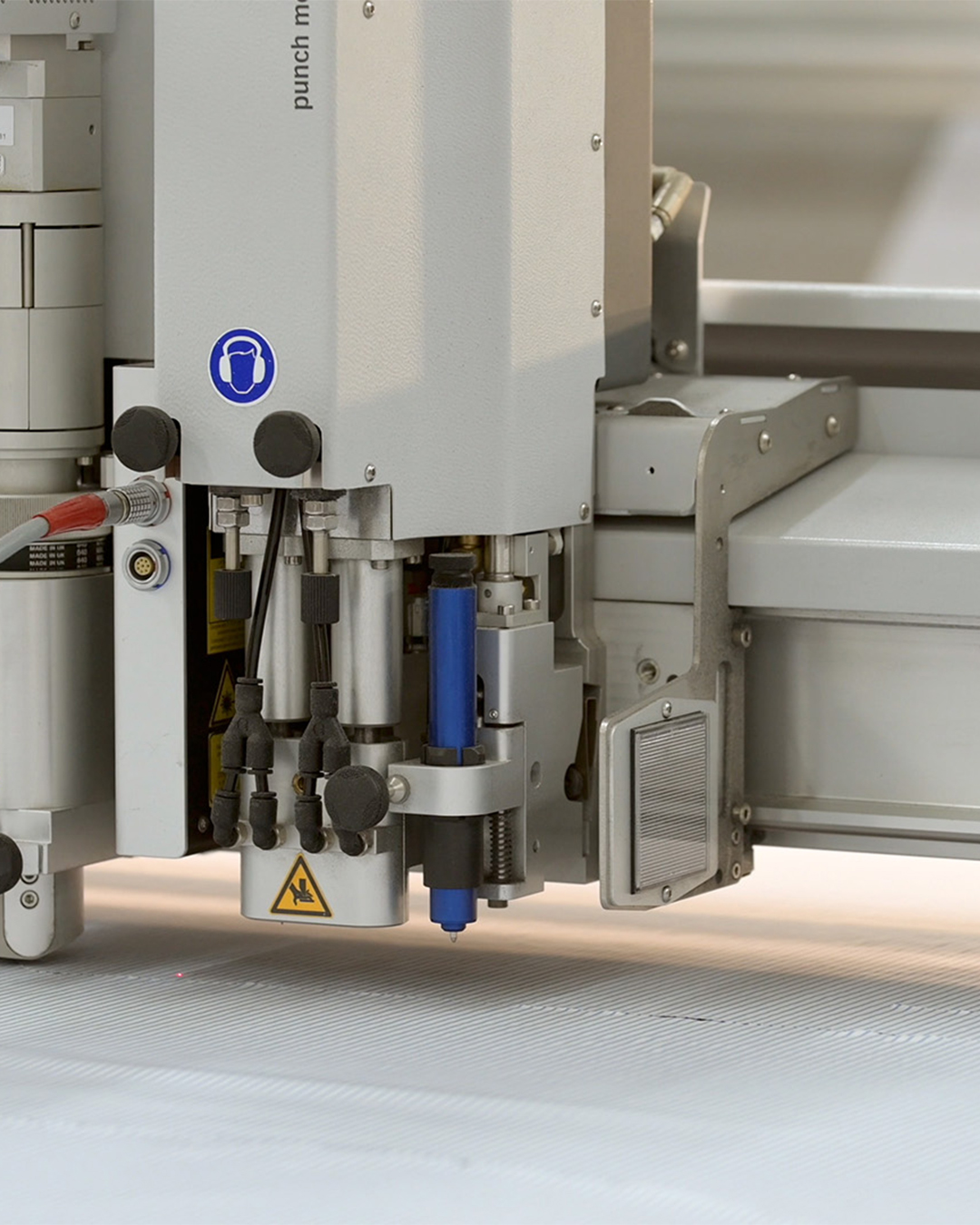

In shirtmaking, where the men’s shirt may appear simple yet is technically complex, 3D can be a useful tool to analyze proportions, balance between components and pattern coherence. But it is only through dialogue with the workshop that the project truly takes shape. The same principle guides our work inside our sartorial laboratory, where technology and craftsmanship coexist without overlapping.

A Practical Example of 3D Sampling

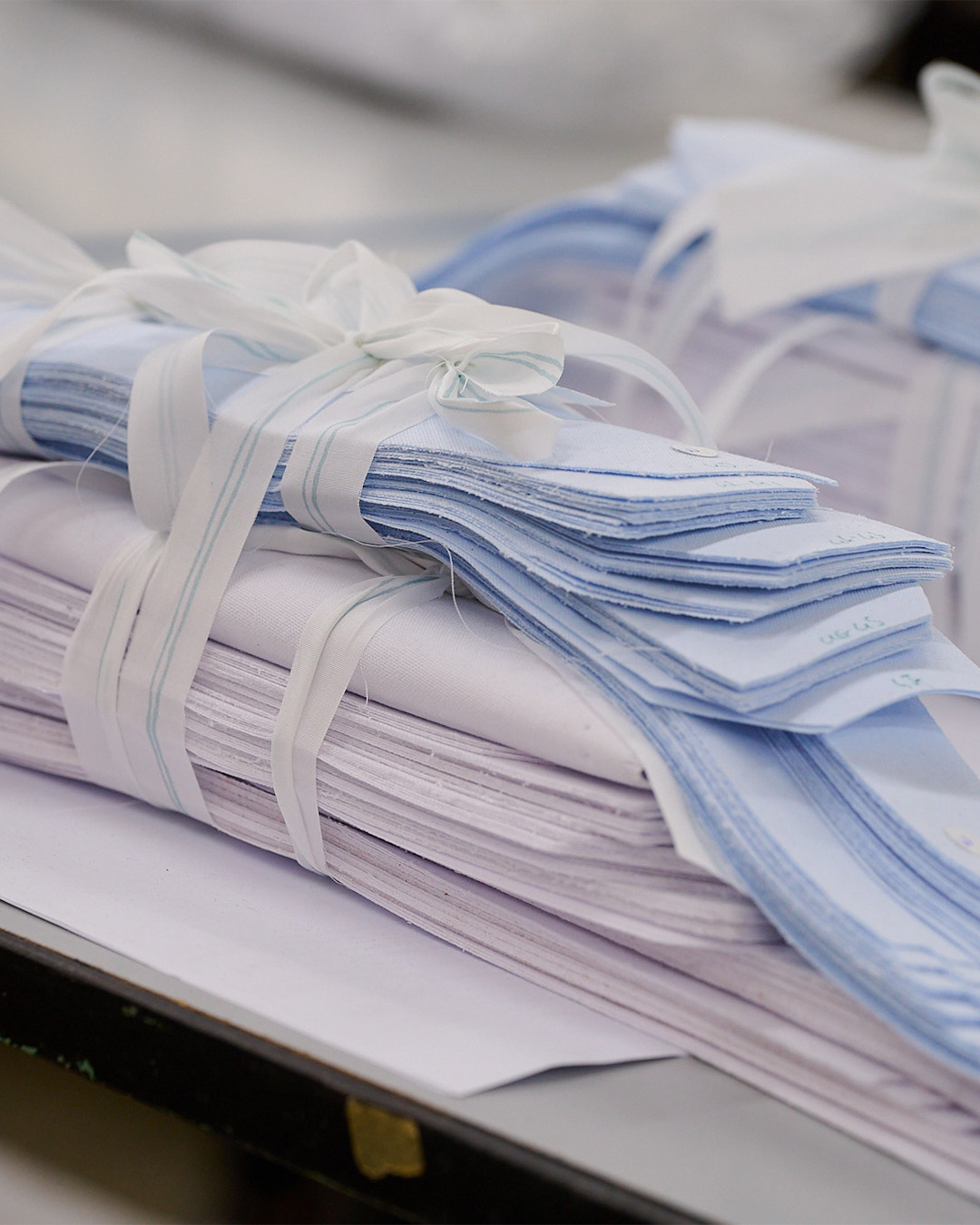

Let us consider a bespoke shirt or a men’s shirt intended for mid to high-level sartorial production. The traditional process involves pattern development, creation of a first physical prototype, fitting, corrections and often a second or third iteration before reaching the final sample.

With 3D fashion prototyping, part of this work can be anticipated. The pattern is built digitally and simulated on an avatar reflecting the target measurements. At this stage, valuable insights immediately emerge: a shoulder that sits too far forward, excess volume in the chest, a dart that does not function properly, or a collar that fails to sit correctly.

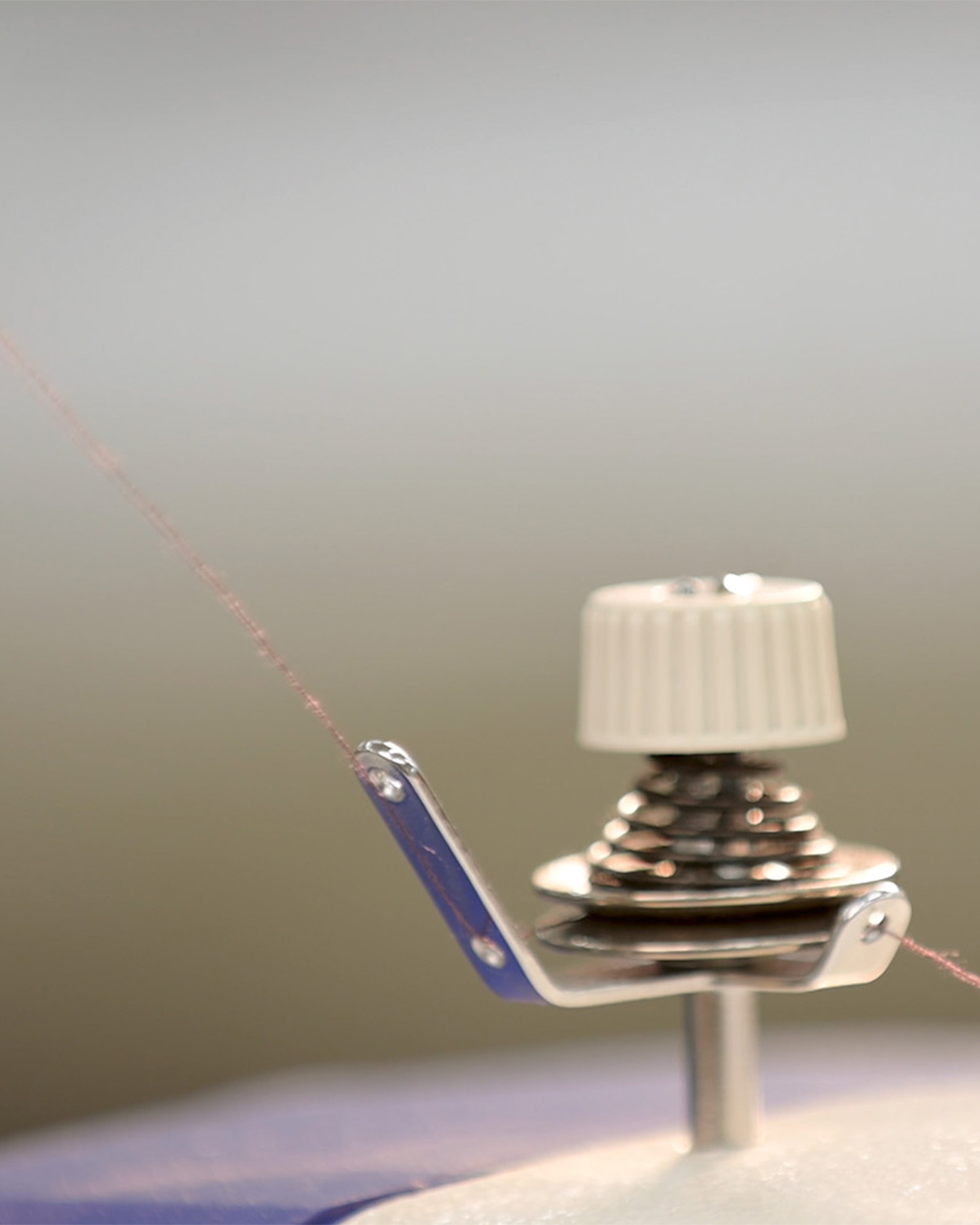

The real advantage is not simply “seeing the garment beforehand,” but understanding where intervention is required at an earlier stage. This reduces the number of physical prototypes needed and allows sartorial work to focus on what truly matters: fabric hand, internal construction and finishing details.

In our third-party sampling and pattern development services, digital tools can provide valuable support especially in early phases, when decisions are still flexible and modifications have minimal impact. Once structure is defined, however, the transition to the physical garment remains essential, as only real fabric can convey tactile response, behavior and perceived quality.

The 3D Fashion Market

The 3D fashion market has grown rapidly, driven by practical needs. Brands are required to develop increasingly complex collections in shorter timeframes, coordinating teams often distributed across multiple countries. In this context, 3D prototyping offers a shared visual language that facilitates communication between design, product development, merchandising and production.

3D models allow immediate project sharing, variant evaluation and simulation of combinations without multiplying physical samples. This proves particularly useful in pre-collection phases, capsule projects or when working across different markets with distinct requirements.

Yet the market must be observed realistically. 3D performs best on garments with relatively standardized constructions. When complex materials, advanced sartorial techniques or details heavily dependent on fabric behavior come into play, simulation loses accuracy. This is why many brands have abandoned the idea of fully replacing physical sampling and have instead adopted a hybrid approach.

Such an approach aligns with a mature industrial vision, similar to what we describe in our page dedicated to industrial efficiency, where the goal is not to accelerate at any cost, but to optimize processes without compromising quality and control.

Revolution or Passing Trend? A Critical Analysis

Is 3D fashion prototyping truly a revolution, or does it risk becoming a passing trend? The answer depends on how it is used. When adopted merely as a visualization tool without integration into pattern development, technical sheets and production flow, it risks remaining a purely aesthetic exercise.

Its real value emerges when digital tools are embedded within a structured system. A solid foundation of sartorial expertise, deep knowledge of materials and a clear process are essential. Without these elements, the 3D model cannot be reliable. Conversely, when developed correctly, it becomes an effective verification tool.

In shirtmaking, for instance, the history of the shirt demonstrates that quality arises from the balance between proportion, construction and fabric use. Elements such as collar roll, cuff response or garment behavior after washing and pressing cannot be fully simulated. This is where the men’s shirt clearly shows that digital tools need tailoring, not the other way around.

From a sustainability perspective, 3D can help reduce waste and unnecessary samples, but only when embedded within a responsible supply chain. This connects closely to material selection, as explored in our pages dedicated to Made in Italy fabrics and ecofriendly materials, where fabric quality significantly influences the final outcome.

Our Advice to Brands

For brands evaluating 3D fashion prototyping, the starting point should be a simple question: where can digital tools genuinely improve the process? The goal is not to adopt technology simply because it is available, but to understand in which phases it adds tangible value.

3D works effectively in preliminary development, proportion verification and cross-department alignment. It becomes less effective when used as a substitute for physical fitting. For this reason, the most solid approach remains hybrid, where digital tools and tailoring collaborate.

In our third-party shirtmaking work, also reflected in our page dedicated to master shirtmakers, value stems from integrating new tools within consolidated expertise. Sartorial production and the production process remain the core of the project, while digital tools serve as allies that make the path more informed and efficient.

Ultimately, 3D prototyping is not a shortcut, but a shift in perspective. It works when it supports better decisions, reduces errors and protects garment value. The future of fashion will be increasingly hybrid: digital in design, physical in the truth of the product. And as always, quality will make the difference.